The grinding process between the ball mill and the basic roller mill is very different. In the ball mill, the grinding process takes place by impact and friction. In mill rollers the grinding process takes place by high grinding pressure to smash the particles in the grinding pad. It is therefore necessary to have a suitable and stable grinding pad defined between the grinding table and the roller in the vertical milling machine. Crushed milling buffers are always easy to achieve when milling the material in a high performance vertical milling machine. However, it is more difficult to have a stable grinding pad when grinding cement because:

- Cement is finer than raw material

- Feeding to conventional cement grinding machines is completely dry and grinding cement is more difficult when raw materials.

Demand for grain size distribution when crushing cement is more severe when milling raw materials

The difference between cement grinding and grinding provides a great challenge to achieve good cement grinding performance with vertical roller mills. However, now the OK crusher, a FLSmidth-type vertical roller mill, has become a model design that has overcome the rigid grinding conditions for cement clinker milling and similar products.

This OK grinder was developed by Onoda Cement, Onoda Technology and Technology Company and Kobe Steel Company in Japan in the 1980s. In 1993, FLSmidth-Fuler acquired the rights to manufacture and sell crushers. this to the market.

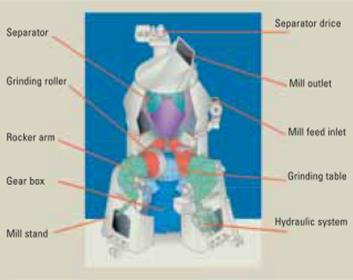

In terms of defining a stable grinding pad, the OK roller grinder design and grinding table is a great big pride invention. As shown in Figure 1, the rollers of the OK mill are spherical and have a groove in the middle. The grinding table is also bent to form a crushing and compression area between the rollers and the grinding table. This is an optimal design for grinding the clinker as it provides two different regions, the low pressure zone and the high pressure zone as shown in Figure 2.

Figure 1. Distribution of radial pressure in the working area of the OK mill

The low pressure zone below the inner surface acts to hold the gas and harden the material when grinding. The proper grinding process takes place at the high pressure zone below, outside the roller. The groove between the rollers holds the gas that makes the material solid.

For a more stable operation with small vibration, this OK grinder has a high performance separation. This results in a fine cycle of fine powder circulation within the mill and a high feed rate respectively. The pulp on the grinder will therefore be more coarse and thus less flexible and thus more effective.

Experience in the field of industry has made it clear that due to the design of the highly efficient milling and disassembling components, the OK mills (Figure 3) fully show all the grinding conditions that are so complex. cement grinding and similar products, allowing for high grinding performance and stable operation. However, although roller mills are generally well used for grinding cement and similar products, the grinder is still poorly grinded to a finer grinding mill and feed rate to the mill.

Figure 2. Typical OK crushing machine

3 Product quality

The grinding system has the objective of grinding the powder to a fineness that meets the requirements of cement strength. The fineness of the cement product is always controlled by the Blaine method or by the amount of flux retarded. However, the quality of this grinding system can be more complex as reflected by Blaine or by sieves. These include the following elements:

- particle size distribution

- Water gypsum of the plaster mixed with cement

- Early hydration and degeneration of minerals in clinker

Duyen Ha cement